Are you looking for systems that recover waste oil or solvents into high quality products?

Oil Re-refining systemsSolvent Recovery

PESCO custom designs, engineers, and fabricates each turnkey system to meet your specific project needs.

Each of these services are explained in detail (below):

-

Lab Services

-

Oil Re-Refining Systems

-

Distillation Systems

-

Hydrotreatment

-

Used Solvent Systems

-

Biofuel Systems

-

Ethanol

-

Biodiesel

Lab Services

At PESCO we utilize our lab to verify client streams for new systems and existing systems that may need our assistance. Analysis tells us many things and most of the time our customers are surprised to what they learn about their waste oil streams or bi-product. In the lab, we use cutting edge methods for analysis backed by many years experience.

Oil Re-refining Systems

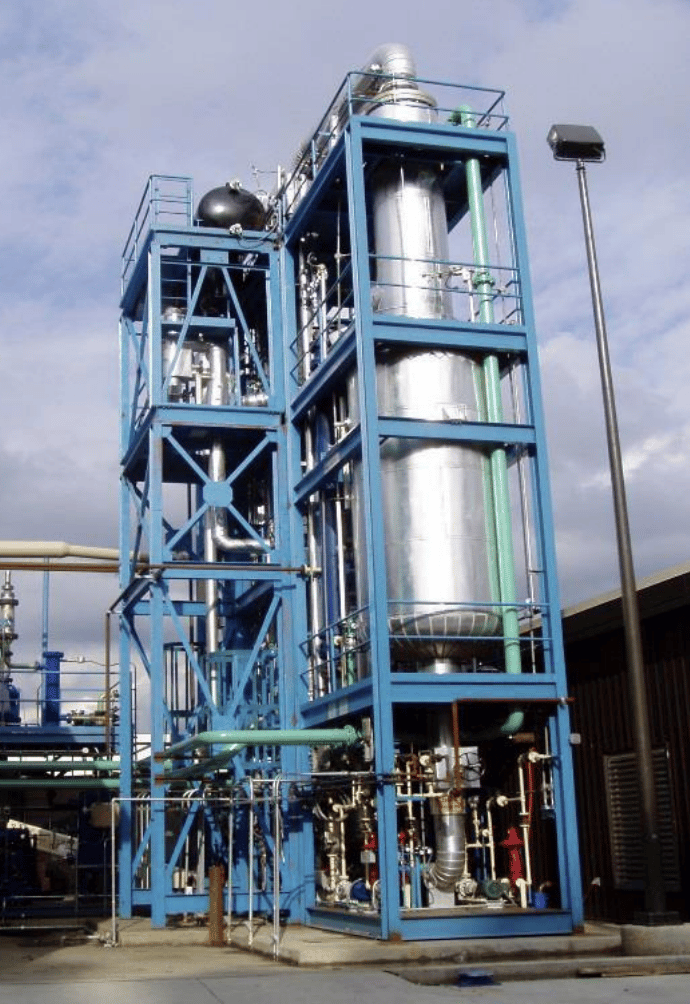

PESCO designs and builds systems which recover useable, clean lubricating oils and diesel fuel from dirty, used crankcase oils, hydraulic oils, mist oils, and other contaminated waste oil. These systems are skid mounted and completely assembled. Thirteen Used oil re-refining systems built by us are in operation at various locations in the world.

PESCO has a unique approach to Used Oil Re-refining, combining many aspects that produce a superior product, without producing more waste which can damage the environment.

Up to Gallons/Hour

- Our waste oil treatment systems are as small as 50 Gallons per hour to as large as 7500 Gallons per hour, rated for 24 hours continuous operation for 330 days a year.

- They are less expensive than most comparable types.

- Our multistage systems can deal with a large variety of feed oils.

- Our design will address your product requirement from VGO (vacuum gas oil) to the finest base lubes and anything in-between.

- Combined with our Regenerative Media Based Polishing system, our systems give lubes to Group 1 and depending on the feed stock, Group 2

- When our client seeks products to Group 2+ then we offer the Hydrotreating system with our re-refining plant.

- Our systems are PLC controlled and function automatically. They can also be monitored from PESCO offices for extended operational support.

Distillation Systems

- PESCO’s Oil Reycling Systems use atmospheric distillation to remove light ends, water, and gas-oil.

- This is followed by high vacuum thin film evaporators which operate at moderately high temperatures to recover the lube oil fraction.

- The temperatures and pressures ensure no “cracking” of the lube fractions.

The residual sludge and solids exiting the system can be used for roads, or low grade bunker 6

Hydrotreatment

- PESCO also recognizes the need to supply hydrotreaters to those larger plants where the client wanted the highest quality results from a long established and proven technology – Hydrofinishing.

- We engage Green Industrial Technologies Ltd. (GIT) of Greece to supply these plants under our banner. GIT have extensive experience in this field, having worked in the hydrotreating sections of major refineries.

- They have also designed, constructed and commissioned a Hydrotreater which has been operating for several years with an excellent record of consistent operation and high quality product.

- Their technology is the most advanced and efficient that we have come across, with many innovations which reduce operating costs, reduced hydrogen consumption, and have a high degree of energy efficiency.

Solvent Recovery Systems

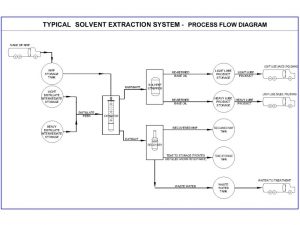

Solvent Recovery Systems

When engineering a solvent recovery system we take the time to become familiar with our customer’s unique situation to provide the most effective solution within their budget. Whether it’s installing a completely new system or replacing components of the existing one, we can provide the services and features that will meet the customer’s needs.Pesco is a synergy of cutting edge design, in-the-trenches experience, top engineering ability and global standard manufacturing. With over 25 years of environmental engineering experience in building affordable, turn-key, reliable, skid mounted, state-of-the-art solvent recovery plants. Our experts will design the perfect custom solution for any facility complete with remote system monitoring and automation solutions that deliver accurate and timely information to system operators.

Disposing of waste solvents can be costly and time consuming. Have you even considered what the other environmental approaches are available? When compared to disposal you could be earning dollars instead of spending them.

Solvent Recovery Systems Built By Pesco

Pollution Control Industries, Now Tradebe Environmental Services, LLC of Chicago, Illinois.

Pesco has designed and built a 1,200 Liter per hour hazardous industrial solvent recovery system for PCI. It separates light hydrocarbons from a middle cut oils and heavy cut oils, as well as from solids. The system has been in operation since early 2005. Since then PCI has ordered and received a second Solvent Recovery System from Pesco which includes a thin film evaporator. This system has been commissioned in June of 2009 and has been operating since then. Design capacity 500 GPH.

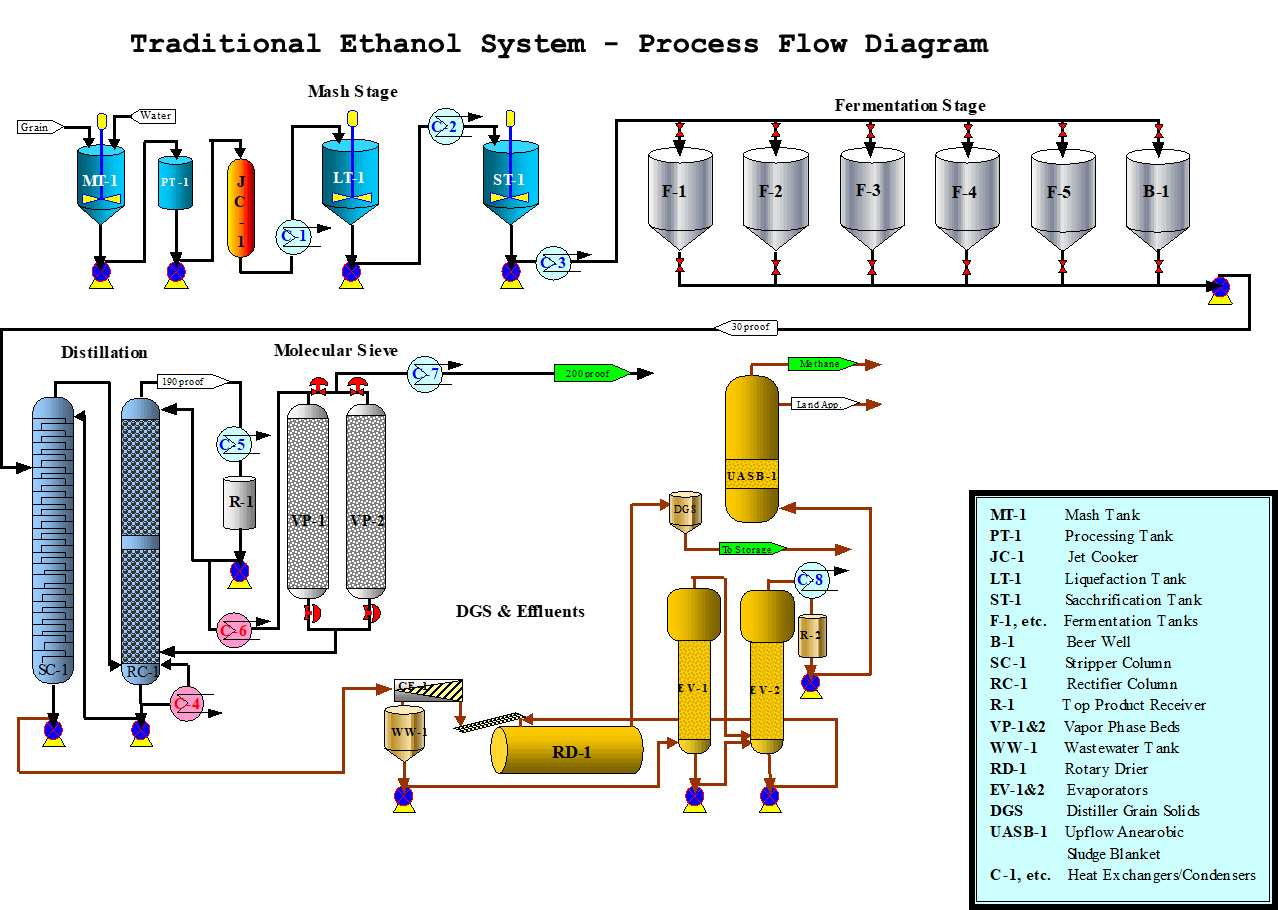

Biofuel Systems – Ethanol

Pesco designs and builds a range of right-sized biofuels manufacturing plants to produce high quality liquid and gas fuels and valuable byproducts from a variety of feedstocks. Pesco’s processing systems enable biofuel producers to realize greater profitability through lower startup costs, consistent and reliable product quality, stronger supplier and consumer relationships, distributed feedstock, direct market connectivity and smarter manufacturing.

These Biofuels systems include processes for batch and continuous biodiesel production and for both traditional and celluosic ethanol production. These systems use technologies and approaches that encourage the use of sustainably-sourced feedstocks to maximize the attributes of the biofuels produced. Depending on your goals and the specific conditions of you project, Pesco will deliver custom state of the art answers to all of you needs.

Biofuels Services

- Cellulosic Ethanol Systems

- Traditional Ethanol Distillation

- Mulit-Stage Fractionation Systems

- Clay Filtration systems

- Biodiesel-Batch Systems

- Biodiesel-Continuous Systems

- Molecular Sieves

- By-Product Recovery Systems

- Methane Digestors

- DDG Systems

- Mobile Systems

- On-site Training

- Troubleshooting existing systems

Bio-Diesel

- PESCO’s Biodiesel Systems are the most complete systems of the market today.

- They include all the process modules to deal with a wide variety of feedstock, including yellow grease, canola oil, soy oil, palm oil and also animal fats.

- PESCO’s systems are designed to efficiently convert these fats and oils into biodiesel, obtaining better than 98% conversion.

- They include all the needed modules to recover valuable byproducts such as methanol and glycerin.

- We guarantee that our systems will produce products which will meet ASTM, EU, and Turkish Standards.

- The systems are continuous and computer controlled.